Abstract

A power actuator is used in combination with a door latch of a motor vehicle movable between a locked and unlocked position has a housing, a reversible electric motor in the housing having a rotatable output shaft which defines an axis, and an input gear on the shaft. A threaded output spindle shaft separately from the housing has an output gear mesh and out of engagement with the input gear. A nut is screwed onto the shaft. A pair of drive elements of the nut with the pin to turn from their positions. A support housing pivotable around the shaft carries a meshing gear pair in mesh and accompanying with the input gear. The support is tiltable about the axis from a central position in which none of the meshing gear meshes with the output gear in a pair of end positions in each of which a respective one of the coupling gears meshing with the gear pairs of the same output and the input gear. The support is biased to the center position with a relatively small force so that the rotation of the input gear in any direction exceeds the biasing force and the support was shaken in the same direction to the final position respectively.

Description

Field of the InventionThe present invention relates to a central locking system for motor vehicles. More particularly, this invention relates to an electric motor drive for such a system.

Background of the Invention

A locking system for motor vehicles standard core has a plurality of door latches at individual doors, hatches, trunk lids, and the like, which are each operable by a respective power actuator, also a manual mechanism. The power actuator may include a hydraulic, pneumatic or electric motor and the manual mechanism is almost always a link lever.In a standard system as described in my U.S. Pat. No. 4,342,209 each door latch has a locking lever movable between a pair of end positions corresponding to the conditions of locking and unlocking of the door respectively. This lever is connected on one side through a rod for the release button on the inside in the case of a door and on the other side through another power to the actuator rod, which is mounted on the door at a distance Lock. Whether or actuator command can be used to lock or unlock the door.As described in U.S. Patent common property. No. 5,056,343 issued October 15, 1991 actuator for a lock of this type system has an electric motor whose output shaft carries a drive pinion which is in constant mesh with an output gear of greater diameter held in a threaded spindle in turn carries a nut. This nut is coupled through a deflectable arm system for the actuator. Thus, the latch can be moved manually or by the motor between the locked and unlocked position. When manually moved from the locked position to the unlocked position, it is necessary that the engine is operated to move the bolt back in the appropriate position before it can resume operation of the propulsion motor.Objects of the InventionTherefore, it is an object of the present invention to provide a device of improved electric motor drive for a central locking system.Another object is the provision of a drive electric motor of this type improved for a central locking system that overcomes the above-given disadvantages, that is which can switch between manual and power operation without loss of cycle.

SUMMARY OF THE INVENTION

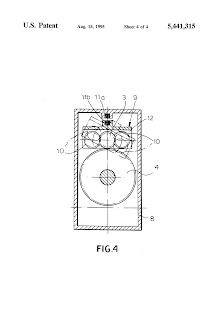

A power actuator is used in combination with a door latch of a motor vehicle movable between a locked and unlocked position is according to the invention a housing, a reversible motor in the housing having a rotatable output shaft which defines a shaft, and an input gear on the shaft. A threaded output spindle shaft separately from the housing has an output gear mesh and out of engagement with the input gear. A nut is screwed onto the shaft. A pair of drive elements of the nut with the pin to turn from their positions. A support housing pivotable around the shaft carries a meshing gear pair in mesh and accompanying with the input gear. The support is tiltable about the axis from a central position in which none of the meshing gear meshes with the output gear in a pair of end positions in each of which a respective one of the coupling gears meshing with the gear pairs of the same output and the input gear. The support is biased to the center position with a relatively small force so that the rotation of the input gear in any direction exceeds the biasing force and the support was shaken in the same direction to the final position respectively.With this system, therefore, there is no need to reverse drive the motor so that the link portions may resume if the proper position after actuation of the power door lock is operated manually. The power actuator can pick up right where you left off.According to the invention, the housing is U-section and has a pair of sides and a back side bridge. Input gears are mating and between the sides and the biasing means is supported between the rear and the enclosure. The biasing means may be a spring connected between the support and the housing. Alternatively it may include a magnet mounted on the support and a magnet mounted in the housing. When one of the magnets is an electromagnet and the support is demagnetized will remain in its end position after moving therein by rotation of the input gear. This can provide a lock or anti-theft feature, inhibition of manual actuation of the latch until the solenoid is activated.Brief Description of the DrawingsThe foregoing and other objects, features and advantages will become more readily apparent from the following description with reference to the accompanying drawings in which:. Figure 1 is a schematic section through part of the actuator of the present invention;. Figure 2 is a section taken along line II - II of FIG. 1;. Figure 3 is a view similar to FIG. 1, another actuating device according to the invention;. Figure 4 is a section taken along line IV - IV of FIG. Three.Specific descriptionAs seen in the figures. 1 and 2 a housing of the actuator 8 typically mounted on a motor vehicle door contains a reversible electric motor 1 operated by a central controller block 16 and having an output shaft 2 which carries an input gear 3 and focused on a 3A axis. A threaded spindle 5 in the housing 8 rotatable about an axis parallel to the axis 3A 5A has an output gear of large diameter with a level 4 but does not mesh with the gear 3 and a nut 6. An operating lever 7 has one end coupled to this nut 6 and an opposite end coupled to a door latch 14. The movement of the lever 7 in a direction unlocks the door latch 14 in the opposite direction and blocks it.

A manual locking / unlocking element 15 is coupled to the lever 7 so that the door can be locked or unlocked manually.According to the invention, a U-section 9 is swing support rotatable about the axis 2 and 3A axle carries a pair of coupling gears so small diameter 10 permanently meshing with the input gear 3 on the axis 2. The holder 9 has a pair of sides 12 between the gears 10 are articulated through which the shaft 2 passes and a flat back 13 closing cheeks or sides 12. This support 9 may range from the central position illustrated in solid lines in FIGS. 2 and 4 and a pair of end positions, illustrated with dash-dotted lines in Figs. 2 and 4. In the central position of either of the gears 3 to 10 engages with the gear 4. In each of the end positions, a respective one of the gears 10 meshes with the gear 4 itself to the gear coupling 3.In the figures. 1 and 2 a spring 11 urges the holder 9 in the center position. In the figures. 3 and 4, a permanent magnet 8 housing 11a cooperates with an electromagnet 11b in the holder 9 and connected to the controller 16 so that, when the electromagnet 11b is energized, the magnetic attraction urges the holder 9 in the center position.During normal use, when the thrust means 11, 11a, 11b is operating, rotation of the gear 3 in one direction will cause all the support 9 to rock in the same direction and the two gears 10 rotate in the opposite direction . One of the gear 10 will engage into the gear 4 and rotate in the same direction as the gear 3. As soon as the engine 1 is stopped, the thrust force will pull the coupling gear 10 of the gear 4 and uncouple the same from one another.If the embodiment of FIGS. 3 and 4 the magnet 11b is not energized, the gear 10 remains in mesh with the gear 4 after the operation of the motor 1 and until the motor 1 is reversed. This will provide an anti-theft function which manual operation of the element 15 is prevented from nut would have to reverse drive the motor 1 through a gear train 4, 10, 3.

0 comments:

Post a Comment