Variable coupling of turbofan engine spools via open differential gear set or simple planetary gear set for improved power extraction and engine operability, with torque coupling for added flexibility

Abstract

A system for transferring mechanical torque varies between a plurality of rotating machines in turbofan engine. Two devices are used, where the first device relies on the magnetic properties of a planetary magnetic gearbox to couple the magnetic machines. The second device is used to variably control the torque transfer between the magnetic machines. The system couples rotating shafts rotating at different speeds within a turbofan engine for controllably transferring power. To transfer power in the system, a fixed gear ratio is obtained by coupling the shafts relatively high and low speed motor to a planetary magnetic gearbox.

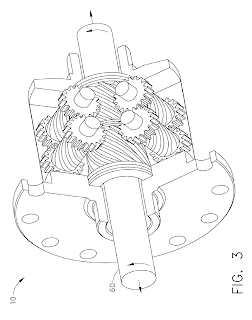

DescriptionField of the InventionThe present invention is directed to a method and apparatus for coupling of rotating machines , and more specifically to coupling of high pressure (HP) and low pressure (LP) turbine shafts of a turbofan machine .Background of the InventionA gas turbine engine generally includes one or more compressors followed in turn by a combustor and turbines of high and low pressure . These engine components are arranged in serial flow communication and disposed about a longitudinal axis centerline of the engine within an annular outer casing . The compressors are driven by the respective turbines and air compressors during operation. The compressed air is mixed with fuel and ignited in the combustion chamber to generate hot combustion gases . The flow of combustion gases through the turbines of high and low pressure , which extract the energy generated by the hot combustion gases to drive the compressors , and for producing auxiliary output power .The engine power is transferred either as shaft power or thrust for powering an aircraft in flight . For example, in other rotatable loads , such as a fan rotor of a turbofan engine by-pass , or propellers in a propeller engine gas turbine , energy is extracted by turbine high and low pressure to the driving the respective fan rotor and the propellers.Well understood that individual components of turbofan engines , in operation, require different power parameters . For example, the fan rotational speed is limited to a degree by the tip velocity and , since the fan diameter is very large, rotational speed must be very low . The core compressor , on the other hand , because of its much smaller diameter , can be driven at a higher rotation speed . Therefore, the separate turbines and low pressure high power transmission devices are needed to separate the compressor and the central fan in gas turbine engines for aviation . Furthermore, since a turbine is most efficient at higher rotational speeds , the lower speed turbine driving the fan requires additional stages to extract the necessary power.Many new aircraft systems are designed to accommodate electrical loads are greater than the current aircraft systems . The specifications of electrical systems for commercial aircraft designs are currently being developed may require up to twice the power of current commercial aircraft . This increased electrical power demand must be derived from mechanical power extracted from the engines that power the aircraft. When operating an aircraft engine at relatively low power levels , for example , doing nothing while descending altitude, the extraction of this additional power engine mechanical power can reduce the ability to operate the engine properly .Traditionally , electrical power is extracted from the high pressure (HP) engine spool in a gas turbine engine . The relatively high operating speed of the HP engine spool makes it an ideal source of mechanical power to drive electrical generators connected to the engine . However, it is desirable to obtain energy from additional sources within the engine , instead of relying solely on the spool engine HP to drive electric generators . The LP engine spool provides an alternate source of power transfer , however, the relatively low speed LP engine spool typically requires the use of a gearbox , as slow-speed electrical generators are often larger than the generators similarly rated electrical operating at higher speeds. However, extracting this additional mechanical power from an engine when it is operating at relatively low power levels (eg , at or near idle descending from altitude, low power for taxi, etc. ) may reduce the operability of the engine. Therefore, it is desirable at times to increase the amount of power that is available on this spool , by transferring torque and power to it via some other means.Another source of power within the engine is the low pressure (LP) spool , which typically operates at speeds much slower than the HP spool , and over a range of relatively wider speed . Take this power low-speed mechanical energy without impractically large generators transformation result . Many solutions have been proposed to this transformation , including various types of conventional mechanical transmission , gearing , and electromechanical configurations .One solution is a turbine engine that utilizes a third , intermediate-pressure (IP ) spool to drive a generator independently. However, this third spool is also required at times to couple to the HP spool. The means used to couple the IP and HP spools are mechanical clutch or coupling mechanisms viscous .U.S. Patent . No. 6,895,741 , issued May 24, 2005 , and entitled " Differential Geared turbine engine capacity modulation pair " describes a mechanically geared motor with three axes. The fan , compressor, and turbine shafts are mechanically coupled by applying the additional epicyclic gear arrangements . The effective gear ratio is variable through the use of electromagnetic machines and power conversion equipment .A pair of detection Torsen ® ( Torsen ® is a registered trademark of JTEKT Torsen North America Inc.) is a mechanical device that operates without electronic controls, clutches or viscous coupling . Detecting Torsen ® differential pair is known for its use in all -wheel drive vehicles . When the torque is distributed equally to all wheels, the differential is open . If one or more wheels begins to lose traction, the torque differential causes the gears in the Torsen differential torque sensing ® to the mesh. Torque detection ® Torsen differential is typically designed with a gear ratio or bias ratio , which determines the amount of torque applied to the traction wheel relative to the torque applied to the slipping wheel . Torsen differential pair ® sensors are commonly used to transfer power between the rear wheels of front wheel drive vehicles and rear. Torque detection ® Torsen differential transfers torque to the stable wheels before actual slippage occurs .Therefore, what is needed is a system for coupling multiple shafts rotating at discreet speeds in an engine to extract power .SUMMARY OF THE INVENTION

The present invention relates to a system for transferring mechanical torque varies between a plurality of rotating machines in a turbofan engine . The system couples rotating shafts rotating at different speeds within a turbofan engine in a controlled transfer of power between them . To transfer power in the system, a fixed gear ratio is obtained by coupling the shafts relatively high and low speed motor to a magnetic gearbox . A torque detection mechanism then may be employed within the epicyclic gear train to transfer power from the LP spool to the HP spool , thereby reducing the required power extraction from HP spool. Alternatively, a magnetic device that relies on the properties of a planetary gearbox can be used instead of an epicyclic gearbox . This arrangement provides the advantage of eliminating the need to mechanically couple the motor windings . This controlled power transfer can be particularly advantageous for extracting increased amounts of mechanical power from an engine, or to improve the dynamic performance of the motor. While the energy is transferred between the reels and auxiliary engine loads purely by magnetic forces , there is the opportunity to decouple any or all loads to meet operational requirements . The HP spool can be decoupled from the LP spool for engine starting, as an example, or the spools can be decoupled to increase transient response by removing the coupled inertia of the other elements. In a preferred embodiment , additional gearing is provided in order to allow a full range of operability. Another advantage of the present invention is that variable power transfer between the engine shafts is accomplished without a mechanical connection between the motor shafts .The present invention is also directed to a method for coupling a reel variable high-pressure and low-pressure spools of a turbofan engine to power a generator. The method includes the steps of providing a differential gear portion and electromagnetic variable transmission , coupling the electromagnetic variable transmission with the high pressure spool and the low pressure spool and the transfer of torque between controllably high pressure spool and low pressure spool through the EVT . The method also includes the steps of connecting the differential gear portion between the high pressure spool and low pressure spool in parallel with the electromagnetically variable transmission , a rotational speed equaling the high pressure spool , a rotational speed the low pressure spool , and an output speed of an output shaft of the differential gear portion and driving the generator by mechanically coupling the generator to the output shaft .In another aspect, the present invention is directed to a gas turbine engine . The turbine engine includes a compressor , a combustor , a turbine high pressure and low pressure turbines arranged in serial flow communication and disposed about a longitudinal axis of the engine within an annular outer casing . The compressor is driven by the high pressure and low pressure turbines and compressor air during operation. A variable coupling part is also provided for coupling a high pressure spool and low pressure spools to power a generator in a turbofan engine . The variable part of coupler includes a differential gear portion having a first input , a second input portion and an output shaft . An electromagnetic variable transmission has an inner rotor portion and independently rotatable outer rotor portion rotating independently . The inner rotor portion is coupled with either the high pressure spool or the low pressure spool , and the outer portion connected to the remaining spool , to transfer torque between the high pressure spool and low pressure spool. The differential gear portion is connected between the high pressure spool and low pressure spool in parallel with the electromagnetically variable transmission . The generator is mechanically coupled to the output shaft. The differential gear portion is arranged to equalize the rotational speed of the high pressure spool , the low pressure spool , and the output speed of the output shaft for driving the generator. The EVT is arranged to controllably couple power from the low pressure spool to high pressure spool .The present invention may be located either inside or outside the engine nacelle or housing. While the variable magnetic gearbox of the present invention is described in association with a turbofan engine , it is considered within the scope of the invention to apply the variable magnetic coupling to any mechanical equipment requiring variable torque transmission , for example, hybrid auto transmissions .In some cases of the present invention may also be desired to couple additional power on HP spool. When additional energy is transferred and made available to the LP spool HP , the energy division can be set more towards the HP spool. This can result in a speed range lower than the load. The mechanisms for accomplishing this added coupling , and the benefits thereof, are within the scope of the present invention and explained in more detail below.Described a system for coupling additional power to the HP spool uses electromagnetically variable transmission ( EVT ) . The EVT permits controllable coupling of torque from the LP spool to the HP spool , when added power is needed from the HP spool. To provide this function , open differential relations can be selected to divert the power draw more heavily on the HP . A planetary gear box ( PGB ) may also be substituted for the open differential , since the PGB performs the same function of splitting torque and speed . Thus, it reduces the speed range the differential output (or PGB carrier ) . In turn, this permits the sizing of an electrical generator to be more favorable , as well as the electrical operating frequency of the connected power system . This allows the use of the EVT where physically smaller systems require .Another method for coupling additional power to the HP spool is through the application of a limited slip differential . In a conventional automobile application , limited -slip differential prevents the wheel speeds from diverging by more than a configured amount , by providing extra torque to the slower wheel , and less to the faster wheel . This helps ensure that the power transmitted to both wheels remains within a desired range . The same principle applies in the present invention where the HP spool and LP spool input speeds to the differential are such that the slip -limiting mechanism of the differential is engaged and biases the torque transmission more strongly from the HP spool during certain engine operating conditions . A system for providing such a torque biasing is a Torsen differential ® . The Torsen differential ® to provide a pair of polarization are based in part on friction to transmit torque using thrust plates , but it does not require clutches or disks that are typically subject to higher wear rates .The present invention allows the extraction of energy from either of the engine spools of a turbofan engine in a configurable system and dynamic. It also provides the ability for an electrical generator system to draw power smaller than the LP spool turbine than would be possible otherwise . Furthermore, the present invention provides greater capability in designing the airframe electrical power system , while minimizing the impact on engine operability . Coupling the torque from both the LP spool turbine and the torque of the HP turbine spool provides a solution to the problem of energy extraction . Furthermore, the use of the coupling system with a differential pair (or PGB ) enables the interoperability of machines of different sizes and types. Furthermore, applying an EVT device permits controlled coupling of torque , without any mechanical contact between the HP spool and LP spool turbines. A limited slip differential of the present invention enables torque thrust to further improve the operating speed range at the load.Other features and advantages of the present invention will become apparent from the following detailed description of the preferred embodiment, taken in conjunction with the accompanying drawings which illustrate, by way of example, the principles of the invention.BRIEF DESCRIPTION OF THE DRAWINGS. Figure 1 is a longitudinal sectional view schematic illustration of a gas turbine engine turbofan aircraft exemplary.. Figure 2 is a power flow diagram describing the arrangement of a EVT to bias torque between engine spools while delivering power to the generator.. Figure 3 is a fragmentary view of the Torsen differential torque sensing ® of the present invention .. Figure 4 is a schematic diagram in cross section of an electromagnetic variable transmission ( EVT ) .Wherever possible , the same reference numbers will be used throughout the drawings to refer to the same or similar parts .DETAILED DESCRIPTION OF THE INVENTION Illustrated in FIG . 1 is an exemplary turbofan engine 10 having an axis which extends generally axially or centerline 12 extending generally in a forward direction 14 and an aft direction 16. The bypass turbofan engine 10 includes a core engine 18 (also called a gas generator ) which includes a high pressure compressor 20 , a combustor 22 and a high pressure turbine (HPT ) 23 having a row blades of high pressure turbine 24 , all arranged in a series flow relationship , axial . High pressure compressor blades 64 of the high pressure compressor 20 are fixedly connected in driving engagement to the blades of the high pressure turbine 24 by a motor shaft of a larger diameter annular core 26 which is disposed coaxially around centerline 12 of the engine 10 forming a high pressure spool 21.A combustion chamber 22 in the core engine 18 mixes pressurized air from the high pressure compressor 20 with fuel and ignites the resulting fuel and air mixture to produce combustion gases. Some work is extracted from these gases by the blades of the high pressure turbine 24 which drives the high pressure compressor 20 . The combustion gases are discharged from the core engine 18 into a power turbine or low pressure turbine (LPT ) 27 having a row of blades of the low pressure turbine 28. The blades of the low pressure turbine 28 are fixedly attached to a shaft diameter smaller annular low pressure 30 , which is disposed coaxially about the centerline 12 of the engine 10 within the core engine shaft 26 forming one low-pressure spool 29. The low pressure shaft 30 rotates axially spaced first and second stage fans 31 and 33 from a motor fan section 35 . The first and second stage fans 31 and 33 include first and second stage rows of generally radially outwardly extending and circumferentially spaced-apart first and second stage fan blades 32 and 36 , respectively.A fan bypass duct 40 circumscribes the second level of the fan motor 33 and the base 18. Core discharge airflow 170 is discharged from the low pressure turbine 27 to mix with bypass airflow 178 discharged from the fan bypass duct 40 through a rear variable area bypass injector ( Vabi ) 53 . Mixing is carried out in an exhaust pipe 69 that forms the exhaust flow , which is discharged through an exhaust nozzle variable area 122. An optional afterburner 130 can be used to increase the potential thrust motor 10.Referring now to FIG . 4, an Electromagnetic Variable Transmission ( EVT ) includes a hollow cylindrical outer rotor portion 114 and a cylindrical hollow inner rotor 112. The inner rotor portion 112 is located within a central aperture of the outer rotor 114. Rotor portions 112, 114 are mutually independently rotatable . The inner rotor portion 112 is independently rotatable within the outer rotor portion 114. The outer rotor portion 114 is independently rotatable circumferentially about the inner rotor portion 112. The outer rotor portion 114 has a plurality of permanent magnets pairs 118 spaced about an inner or first surface 120. The magnets 118 are configured in pairs and facing an air gap . The air gap is disposed between the outer rotor and the inner rotor part . The other portions of the outer and inner rotor having a plurality of slots spaced about a magnetically permeable core portion . The portion of outer rotor and the inner rotor are both rotatable in one direction. In response to co - rotating the outer rotor portion and the inner rotor part , it generates a magnetic flux path between the plurality of permanent magnet pairs , the air gap and the inner rotor portion core . The magnetic flux path induces electric current in the windings and causes mechanical energy to be transferred between the inner rotor portion 112 and the outer rotor 114.Torque transfer is achieved between the rotation axis at the same time through a rotating electromagnetic field without any mechanical connection between the two shafts . Current induced field is all that is required to generate electromagnetic fields.Electromagnetic Variable Transmission ( EVT ) 110 includes two rotating components , an inner rotor 112 and an outer rotor 114 . Both the inner rotor 112 and outer rotor 114 rotate in the same direction around a common axis. The inner rotor 112 has multiple pairs of permanent magnet poles 118 opposite the inner surface 120 of the outer rotor 114. The rotor core 128 is similar in construction to a permanent magnet rotor ( PM) in an electric machine PM inside out . A more detailed description of the EVT is set forth in U.S. Patent Application . No. 11/ 567, 592, assigned to the assignee of the present invention and filed on even date herewith , which patent application is incorporated herein by reference as if set forth in full.Referring to FIG . 2, a differential or planetary gear set 50 is connected to the HP spool 54 and LP spool 52 of the motor 10 to enable the desired ratio of power sharing between the spools . In parallel with the differential or planetary gear set 50 , is the electromagnetic variable transmission ( EVT ) 56 to controllably couple power from the LP spool 52 to the HP spool 54 when necessary. The differential 50 is then coupled to the generator 58 to produce energy. For an engine operating condition since the power absorbed by each coil 52, 54 can be divided according to the respective speeds applied at a differential gearbox 50 . For example, if the speed of the HP spool 54 is 10000 rpm , and the speed of the LP spool 52 is 1000 rpm, after gearing the speed of the HP spool 54 down by a ratio of 2:1 and the speed from the LP spool 52 up by a ratio of 5:01 , the resultant velocities in the opposite inputs 62, 64 of the differential 50 will be 5000 rpm, and the differential carrier will also be 5000 rpm. As a load is applied to the differential output , the torque splits equally across the differential input and since the opposing inputs are matched in speed, the power draw from each is equal . As the motor 10 changes the conditions , the division of power between the HP and LP spool 54 reel 52 changes accordingly. The load supplied by the differential output may be either an electrical or mechanical load . When an increase in engine speed occurs, the spool with the greater relative speed change will pick up a larger share of the load. While it may not be optimal for a reel to bear a greater share of the load, the load transfer is a necessary feature of this agreement. The gear set 50 employs a train of gears that operate with a fixed speed relationship based on their relative size and capacity of the HP and LP gears is different in order to achieve the desired speed ratio . The torque on each shaft must be equal in order to maintain steady state operation . Since energy is equal to the speed torque , the total power transferred on each shaft is proportional to the speed that the shaft is spinning. The shaft rotates at a faster speed with the same torque must transmit more power . This device is known as "splitting speed" and not a device to "split the power." This coupling also alleviates a problem of tapping power from the LP spool 52, which often has a very wide range of speeds. A speed variation width between the coils 52, 54 causes difficulty in designing generators and power systems to accommodate the various speeds and speed ranges . Another means to couple the HP spool 54 and LP spool 52 is a mechanical clutch or a mechanism viscous coupling . Viscous coupling means having two sets of plates inside a sealed housing that is filled with a thick liquid . A set of plates is connected to each output shaft. Under normal conditions, both sets of plates and the viscous fluid spin at the same speed . When one spool spins faster than the other , the set of plates corresponding to the spool spins faster than the other. The viscous fluid , stuck between the plates , tries to catch up with the faster disks , dragging the slower disks along . This transfers more torque to the slower moving spool .Additional generator systems and to operate more efficiently at and prefer speed ranges lower ( ie, ratio of maximum speed to minimum speed ) . The mechanical coupling of the HP spool 54 and LP spool 52 enables an averaging of the speeds and speed ranges of both spools. For example, if the LP spool 52 has a speed range of 4 to 1 and the HP spool 54 has a speed range of 2 to 1, the resulting speed range of the load will be 3 to 1. This allows smaller generators and simple to be applied as a burden instead of trying to design a power generator system or to accommodate the widest range of speeds. This gear coupling is also accomplished by using a simple planetary gearbox (not shown ), which made the sun and ring gears of a planetary to be identical in gear size and pitch. For this planetary gear set , one possible arrangement includes one spool geared to the sun gear , and the other spool geared to the ring gear and the carrier geared to the load. When using a planetary gear assembly , the transmission ratios required input of the coils will be different, however, the exact same mathematical conditions can be satisfied with the gear coupling .. Figure 3 illustrates a fragmentary view of a Torsen ® torque sensing differential gear case 50 . Differential gear box 50 is coupled to the HP spool 54 and LP spool 52 spools to distribute the power . The shaft 60 is arranged to run from the differential 50 to the generator ( not shown). The differential 50 allows the HP spool 54 and LP spool 52 to shift their speeds to the differential and average speeds of the two coils 52, 54 to produce a more efficient operating machine 10 .While the invention has been described with reference to a preferred embodiment, be understood by those skilled in the art that various changes may be made and equivalents may be substituted for elements thereof without departing from the scope of the invention . In addition, many modifications may be made to adapt a particular situation or material to the teachings of the invention without departing from the essential scope thereof. Therefore, it is intended that the invention not be limited to the particular embodiment disclosed as the best mode contemplated for carrying out this invention, but that the invention will include all embodiments falling within the scope of the appended claims.

Abstract

A system for transferring mechanical torque varies between a plurality of rotating machines in turbofan engine. Two devices are used, where the first device relies on the magnetic properties of a planetary magnetic gearbox to couple the magnetic machines. The second device is used to variably control the torque transfer between the magnetic machines. The system couples rotating shafts rotating at different speeds within a turbofan engine for controllably transferring power. To transfer power in the system, a fixed gear ratio is obtained by coupling the shafts relatively high and low speed motor to a planetary magnetic gearbox.

DescriptionField of the InventionThe present invention is directed to a method and apparatus for coupling of rotating machines , and more specifically to coupling of high pressure (HP) and low pressure (LP) turbine shafts of a turbofan machine .Background of the InventionA gas turbine engine generally includes one or more compressors followed in turn by a combustor and turbines of high and low pressure . These engine components are arranged in serial flow communication and disposed about a longitudinal axis centerline of the engine within an annular outer casing . The compressors are driven by the respective turbines and air compressors during operation. The compressed air is mixed with fuel and ignited in the combustion chamber to generate hot combustion gases . The flow of combustion gases through the turbines of high and low pressure , which extract the energy generated by the hot combustion gases to drive the compressors , and for producing auxiliary output power .The engine power is transferred either as shaft power or thrust for powering an aircraft in flight . For example, in other rotatable loads , such as a fan rotor of a turbofan engine by-pass , or propellers in a propeller engine gas turbine , energy is extracted by turbine high and low pressure to the driving the respective fan rotor and the propellers.Well understood that individual components of turbofan engines , in operation, require different power parameters . For example, the fan rotational speed is limited to a degree by the tip velocity and , since the fan diameter is very large, rotational speed must be very low . The core compressor , on the other hand , because of its much smaller diameter , can be driven at a higher rotation speed . Therefore, the separate turbines and low pressure high power transmission devices are needed to separate the compressor and the central fan in gas turbine engines for aviation . Furthermore, since a turbine is most efficient at higher rotational speeds , the lower speed turbine driving the fan requires additional stages to extract the necessary power.Many new aircraft systems are designed to accommodate electrical loads are greater than the current aircraft systems . The specifications of electrical systems for commercial aircraft designs are currently being developed may require up to twice the power of current commercial aircraft . This increased electrical power demand must be derived from mechanical power extracted from the engines that power the aircraft. When operating an aircraft engine at relatively low power levels , for example , doing nothing while descending altitude, the extraction of this additional power engine mechanical power can reduce the ability to operate the engine properly .Traditionally , electrical power is extracted from the high pressure (HP) engine spool in a gas turbine engine . The relatively high operating speed of the HP engine spool makes it an ideal source of mechanical power to drive electrical generators connected to the engine . However, it is desirable to obtain energy from additional sources within the engine , instead of relying solely on the spool engine HP to drive electric generators . The LP engine spool provides an alternate source of power transfer , however, the relatively low speed LP engine spool typically requires the use of a gearbox , as slow-speed electrical generators are often larger than the generators similarly rated electrical operating at higher speeds. However, extracting this additional mechanical power from an engine when it is operating at relatively low power levels (eg , at or near idle descending from altitude, low power for taxi, etc. ) may reduce the operability of the engine. Therefore, it is desirable at times to increase the amount of power that is available on this spool , by transferring torque and power to it via some other means.Another source of power within the engine is the low pressure (LP) spool , which typically operates at speeds much slower than the HP spool , and over a range of relatively wider speed . Take this power low-speed mechanical energy without impractically large generators transformation result . Many solutions have been proposed to this transformation , including various types of conventional mechanical transmission , gearing , and electromechanical configurations .One solution is a turbine engine that utilizes a third , intermediate-pressure (IP ) spool to drive a generator independently. However, this third spool is also required at times to couple to the HP spool. The means used to couple the IP and HP spools are mechanical clutch or coupling mechanisms viscous .U.S. Patent . No. 6,895,741 , issued May 24, 2005 , and entitled " Differential Geared turbine engine capacity modulation pair " describes a mechanically geared motor with three axes. The fan , compressor, and turbine shafts are mechanically coupled by applying the additional epicyclic gear arrangements . The effective gear ratio is variable through the use of electromagnetic machines and power conversion equipment .A pair of detection Torsen ® ( Torsen ® is a registered trademark of JTEKT Torsen North America Inc.) is a mechanical device that operates without electronic controls, clutches or viscous coupling . Detecting Torsen ® differential pair is known for its use in all -wheel drive vehicles . When the torque is distributed equally to all wheels, the differential is open . If one or more wheels begins to lose traction, the torque differential causes the gears in the Torsen differential torque sensing ® to the mesh. Torque detection ® Torsen differential is typically designed with a gear ratio or bias ratio , which determines the amount of torque applied to the traction wheel relative to the torque applied to the slipping wheel . Torsen differential pair ® sensors are commonly used to transfer power between the rear wheels of front wheel drive vehicles and rear. Torque detection ® Torsen differential transfers torque to the stable wheels before actual slippage occurs .Therefore, what is needed is a system for coupling multiple shafts rotating at discreet speeds in an engine to extract power .SUMMARY OF THE INVENTION

The present invention relates to a system for transferring mechanical torque varies between a plurality of rotating machines in a turbofan engine . The system couples rotating shafts rotating at different speeds within a turbofan engine in a controlled transfer of power between them . To transfer power in the system, a fixed gear ratio is obtained by coupling the shafts relatively high and low speed motor to a magnetic gearbox . A torque detection mechanism then may be employed within the epicyclic gear train to transfer power from the LP spool to the HP spool , thereby reducing the required power extraction from HP spool. Alternatively, a magnetic device that relies on the properties of a planetary gearbox can be used instead of an epicyclic gearbox . This arrangement provides the advantage of eliminating the need to mechanically couple the motor windings . This controlled power transfer can be particularly advantageous for extracting increased amounts of mechanical power from an engine, or to improve the dynamic performance of the motor. While the energy is transferred between the reels and auxiliary engine loads purely by magnetic forces , there is the opportunity to decouple any or all loads to meet operational requirements . The HP spool can be decoupled from the LP spool for engine starting, as an example, or the spools can be decoupled to increase transient response by removing the coupled inertia of the other elements. In a preferred embodiment , additional gearing is provided in order to allow a full range of operability. Another advantage of the present invention is that variable power transfer between the engine shafts is accomplished without a mechanical connection between the motor shafts .The present invention is also directed to a method for coupling a reel variable high-pressure and low-pressure spools of a turbofan engine to power a generator. The method includes the steps of providing a differential gear portion and electromagnetic variable transmission , coupling the electromagnetic variable transmission with the high pressure spool and the low pressure spool and the transfer of torque between controllably high pressure spool and low pressure spool through the EVT . The method also includes the steps of connecting the differential gear portion between the high pressure spool and low pressure spool in parallel with the electromagnetically variable transmission , a rotational speed equaling the high pressure spool , a rotational speed the low pressure spool , and an output speed of an output shaft of the differential gear portion and driving the generator by mechanically coupling the generator to the output shaft .In another aspect, the present invention is directed to a gas turbine engine . The turbine engine includes a compressor , a combustor , a turbine high pressure and low pressure turbines arranged in serial flow communication and disposed about a longitudinal axis of the engine within an annular outer casing . The compressor is driven by the high pressure and low pressure turbines and compressor air during operation. A variable coupling part is also provided for coupling a high pressure spool and low pressure spools to power a generator in a turbofan engine . The variable part of coupler includes a differential gear portion having a first input , a second input portion and an output shaft . An electromagnetic variable transmission has an inner rotor portion and independently rotatable outer rotor portion rotating independently . The inner rotor portion is coupled with either the high pressure spool or the low pressure spool , and the outer portion connected to the remaining spool , to transfer torque between the high pressure spool and low pressure spool. The differential gear portion is connected between the high pressure spool and low pressure spool in parallel with the electromagnetically variable transmission . The generator is mechanically coupled to the output shaft. The differential gear portion is arranged to equalize the rotational speed of the high pressure spool , the low pressure spool , and the output speed of the output shaft for driving the generator. The EVT is arranged to controllably couple power from the low pressure spool to high pressure spool .The present invention may be located either inside or outside the engine nacelle or housing. While the variable magnetic gearbox of the present invention is described in association with a turbofan engine , it is considered within the scope of the invention to apply the variable magnetic coupling to any mechanical equipment requiring variable torque transmission , for example, hybrid auto transmissions .In some cases of the present invention may also be desired to couple additional power on HP spool. When additional energy is transferred and made available to the LP spool HP , the energy division can be set more towards the HP spool. This can result in a speed range lower than the load. The mechanisms for accomplishing this added coupling , and the benefits thereof, are within the scope of the present invention and explained in more detail below.Described a system for coupling additional power to the HP spool uses electromagnetically variable transmission ( EVT ) . The EVT permits controllable coupling of torque from the LP spool to the HP spool , when added power is needed from the HP spool. To provide this function , open differential relations can be selected to divert the power draw more heavily on the HP . A planetary gear box ( PGB ) may also be substituted for the open differential , since the PGB performs the same function of splitting torque and speed . Thus, it reduces the speed range the differential output (or PGB carrier ) . In turn, this permits the sizing of an electrical generator to be more favorable , as well as the electrical operating frequency of the connected power system . This allows the use of the EVT where physically smaller systems require .Another method for coupling additional power to the HP spool is through the application of a limited slip differential . In a conventional automobile application , limited -slip differential prevents the wheel speeds from diverging by more than a configured amount , by providing extra torque to the slower wheel , and less to the faster wheel . This helps ensure that the power transmitted to both wheels remains within a desired range . The same principle applies in the present invention where the HP spool and LP spool input speeds to the differential are such that the slip -limiting mechanism of the differential is engaged and biases the torque transmission more strongly from the HP spool during certain engine operating conditions . A system for providing such a torque biasing is a Torsen differential ® . The Torsen differential ® to provide a pair of polarization are based in part on friction to transmit torque using thrust plates , but it does not require clutches or disks that are typically subject to higher wear rates .The present invention allows the extraction of energy from either of the engine spools of a turbofan engine in a configurable system and dynamic. It also provides the ability for an electrical generator system to draw power smaller than the LP spool turbine than would be possible otherwise . Furthermore, the present invention provides greater capability in designing the airframe electrical power system , while minimizing the impact on engine operability . Coupling the torque from both the LP spool turbine and the torque of the HP turbine spool provides a solution to the problem of energy extraction . Furthermore, the use of the coupling system with a differential pair (or PGB ) enables the interoperability of machines of different sizes and types. Furthermore, applying an EVT device permits controlled coupling of torque , without any mechanical contact between the HP spool and LP spool turbines. A limited slip differential of the present invention enables torque thrust to further improve the operating speed range at the load.Other features and advantages of the present invention will become apparent from the following detailed description of the preferred embodiment, taken in conjunction with the accompanying drawings which illustrate, by way of example, the principles of the invention.BRIEF DESCRIPTION OF THE DRAWINGS. Figure 1 is a longitudinal sectional view schematic illustration of a gas turbine engine turbofan aircraft exemplary.. Figure 2 is a power flow diagram describing the arrangement of a EVT to bias torque between engine spools while delivering power to the generator.. Figure 3 is a fragmentary view of the Torsen differential torque sensing ® of the present invention .. Figure 4 is a schematic diagram in cross section of an electromagnetic variable transmission ( EVT ) .Wherever possible , the same reference numbers will be used throughout the drawings to refer to the same or similar parts .DETAILED DESCRIPTION OF THE INVENTION Illustrated in FIG . 1 is an exemplary turbofan engine 10 having an axis which extends generally axially or centerline 12 extending generally in a forward direction 14 and an aft direction 16. The bypass turbofan engine 10 includes a core engine 18 (also called a gas generator ) which includes a high pressure compressor 20 , a combustor 22 and a high pressure turbine (HPT ) 23 having a row blades of high pressure turbine 24 , all arranged in a series flow relationship , axial . High pressure compressor blades 64 of the high pressure compressor 20 are fixedly connected in driving engagement to the blades of the high pressure turbine 24 by a motor shaft of a larger diameter annular core 26 which is disposed coaxially around centerline 12 of the engine 10 forming a high pressure spool 21.A combustion chamber 22 in the core engine 18 mixes pressurized air from the high pressure compressor 20 with fuel and ignites the resulting fuel and air mixture to produce combustion gases. Some work is extracted from these gases by the blades of the high pressure turbine 24 which drives the high pressure compressor 20 . The combustion gases are discharged from the core engine 18 into a power turbine or low pressure turbine (LPT ) 27 having a row of blades of the low pressure turbine 28. The blades of the low pressure turbine 28 are fixedly attached to a shaft diameter smaller annular low pressure 30 , which is disposed coaxially about the centerline 12 of the engine 10 within the core engine shaft 26 forming one low-pressure spool 29. The low pressure shaft 30 rotates axially spaced first and second stage fans 31 and 33 from a motor fan section 35 . The first and second stage fans 31 and 33 include first and second stage rows of generally radially outwardly extending and circumferentially spaced-apart first and second stage fan blades 32 and 36 , respectively.A fan bypass duct 40 circumscribes the second level of the fan motor 33 and the base 18. Core discharge airflow 170 is discharged from the low pressure turbine 27 to mix with bypass airflow 178 discharged from the fan bypass duct 40 through a rear variable area bypass injector ( Vabi ) 53 . Mixing is carried out in an exhaust pipe 69 that forms the exhaust flow , which is discharged through an exhaust nozzle variable area 122. An optional afterburner 130 can be used to increase the potential thrust motor 10.Referring now to FIG . 4, an Electromagnetic Variable Transmission ( EVT ) includes a hollow cylindrical outer rotor portion 114 and a cylindrical hollow inner rotor 112. The inner rotor portion 112 is located within a central aperture of the outer rotor 114. Rotor portions 112, 114 are mutually independently rotatable . The inner rotor portion 112 is independently rotatable within the outer rotor portion 114. The outer rotor portion 114 is independently rotatable circumferentially about the inner rotor portion 112. The outer rotor portion 114 has a plurality of permanent magnets pairs 118 spaced about an inner or first surface 120. The magnets 118 are configured in pairs and facing an air gap . The air gap is disposed between the outer rotor and the inner rotor part . The other portions of the outer and inner rotor having a plurality of slots spaced about a magnetically permeable core portion . The portion of outer rotor and the inner rotor are both rotatable in one direction. In response to co - rotating the outer rotor portion and the inner rotor part , it generates a magnetic flux path between the plurality of permanent magnet pairs , the air gap and the inner rotor portion core . The magnetic flux path induces electric current in the windings and causes mechanical energy to be transferred between the inner rotor portion 112 and the outer rotor 114.Torque transfer is achieved between the rotation axis at the same time through a rotating electromagnetic field without any mechanical connection between the two shafts . Current induced field is all that is required to generate electromagnetic fields.Electromagnetic Variable Transmission ( EVT ) 110 includes two rotating components , an inner rotor 112 and an outer rotor 114 . Both the inner rotor 112 and outer rotor 114 rotate in the same direction around a common axis. The inner rotor 112 has multiple pairs of permanent magnet poles 118 opposite the inner surface 120 of the outer rotor 114. The rotor core 128 is similar in construction to a permanent magnet rotor ( PM) in an electric machine PM inside out . A more detailed description of the EVT is set forth in U.S. Patent Application . No. 11/ 567, 592, assigned to the assignee of the present invention and filed on even date herewith , which patent application is incorporated herein by reference as if set forth in full.Referring to FIG . 2, a differential or planetary gear set 50 is connected to the HP spool 54 and LP spool 52 of the motor 10 to enable the desired ratio of power sharing between the spools . In parallel with the differential or planetary gear set 50 , is the electromagnetic variable transmission ( EVT ) 56 to controllably couple power from the LP spool 52 to the HP spool 54 when necessary. The differential 50 is then coupled to the generator 58 to produce energy. For an engine operating condition since the power absorbed by each coil 52, 54 can be divided according to the respective speeds applied at a differential gearbox 50 . For example, if the speed of the HP spool 54 is 10000 rpm , and the speed of the LP spool 52 is 1000 rpm, after gearing the speed of the HP spool 54 down by a ratio of 2:1 and the speed from the LP spool 52 up by a ratio of 5:01 , the resultant velocities in the opposite inputs 62, 64 of the differential 50 will be 5000 rpm, and the differential carrier will also be 5000 rpm. As a load is applied to the differential output , the torque splits equally across the differential input and since the opposing inputs are matched in speed, the power draw from each is equal . As the motor 10 changes the conditions , the division of power between the HP and LP spool 54 reel 52 changes accordingly. The load supplied by the differential output may be either an electrical or mechanical load . When an increase in engine speed occurs, the spool with the greater relative speed change will pick up a larger share of the load. While it may not be optimal for a reel to bear a greater share of the load, the load transfer is a necessary feature of this agreement. The gear set 50 employs a train of gears that operate with a fixed speed relationship based on their relative size and capacity of the HP and LP gears is different in order to achieve the desired speed ratio . The torque on each shaft must be equal in order to maintain steady state operation . Since energy is equal to the speed torque , the total power transferred on each shaft is proportional to the speed that the shaft is spinning. The shaft rotates at a faster speed with the same torque must transmit more power . This device is known as "splitting speed" and not a device to "split the power." This coupling also alleviates a problem of tapping power from the LP spool 52, which often has a very wide range of speeds. A speed variation width between the coils 52, 54 causes difficulty in designing generators and power systems to accommodate the various speeds and speed ranges . Another means to couple the HP spool 54 and LP spool 52 is a mechanical clutch or a mechanism viscous coupling . Viscous coupling means having two sets of plates inside a sealed housing that is filled with a thick liquid . A set of plates is connected to each output shaft. Under normal conditions, both sets of plates and the viscous fluid spin at the same speed . When one spool spins faster than the other , the set of plates corresponding to the spool spins faster than the other. The viscous fluid , stuck between the plates , tries to catch up with the faster disks , dragging the slower disks along . This transfers more torque to the slower moving spool .Additional generator systems and to operate more efficiently at and prefer speed ranges lower ( ie, ratio of maximum speed to minimum speed ) . The mechanical coupling of the HP spool 54 and LP spool 52 enables an averaging of the speeds and speed ranges of both spools. For example, if the LP spool 52 has a speed range of 4 to 1 and the HP spool 54 has a speed range of 2 to 1, the resulting speed range of the load will be 3 to 1. This allows smaller generators and simple to be applied as a burden instead of trying to design a power generator system or to accommodate the widest range of speeds. This gear coupling is also accomplished by using a simple planetary gearbox (not shown ), which made the sun and ring gears of a planetary to be identical in gear size and pitch. For this planetary gear set , one possible arrangement includes one spool geared to the sun gear , and the other spool geared to the ring gear and the carrier geared to the load. When using a planetary gear assembly , the transmission ratios required input of the coils will be different, however, the exact same mathematical conditions can be satisfied with the gear coupling .. Figure 3 illustrates a fragmentary view of a Torsen ® torque sensing differential gear case 50 . Differential gear box 50 is coupled to the HP spool 54 and LP spool 52 spools to distribute the power . The shaft 60 is arranged to run from the differential 50 to the generator ( not shown). The differential 50 allows the HP spool 54 and LP spool 52 to shift their speeds to the differential and average speeds of the two coils 52, 54 to produce a more efficient operating machine 10 .While the invention has been described with reference to a preferred embodiment, be understood by those skilled in the art that various changes may be made and equivalents may be substituted for elements thereof without departing from the scope of the invention . In addition, many modifications may be made to adapt a particular situation or material to the teachings of the invention without departing from the essential scope thereof. Therefore, it is intended that the invention not be limited to the particular embodiment disclosed as the best mode contemplated for carrying out this invention, but that the invention will include all embodiments falling within the scope of the appended claims.

0 comments:

Post a Comment