Apparatus, including gas turbines for the direct driving of vehicles

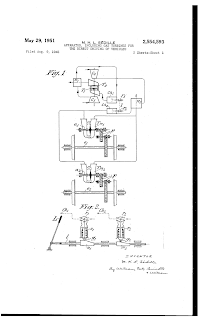

Descriptionand 29 , 1951 M. H. Sedille 2554593Apparatus, including GAS TURBINES FOR DRIVING A MOTOR VEHICLE DIRECT Filed August 9, 1945 2 Sheets sheets 1 to wm om INVQAITOR YLLJalZIL and Sedille 2554593 MHL 1951 equipment, including F0 GAS TURBINE VEHICLES DIRECT DRIVING Filed August 9, 1945 2 sheets - 2 Fact INVENTOR to " ;IVW Patented May 29, 1951 Apparatus, including GAS TURBINES FOR DRIVING A MOTOR VEHICLE DIRECT Sdille Marcel Henri Louis , Paris , France , as-Signor t Societe Rateau ( Société Anonyme ) , Paris , France , a company in France Request August 9, 1945 , Serial No. 609869 In France , August 8, 1941 3 Claims . 1Vehicle driving through a gas turbine is simple when using electrical transmission . However, a certain amount of energy is wasted thereby , and it is preferable to provide a direct mechanical connection between the gas turbine and the vehicle's wheels .To employ a direct mechanical drive , it is desirable that the turbine shaft is guided transversely disposed with reference to the vehicle frame. However, the size of the drive system as a whole can not be mounted in a position transversal and therefore requires the use of a double group comprising one or more turbines driving transversely with reference to the frame, and longitudinally auxiliary group .An obvious solution would of course be to couple driving turbines and parallel auxiliary turbines . However, this provision would by necessity, as evidenced tion calculation to equivalent aperture setting for each turbine in order to provide partial loads power distribution to ensure maximum efficiency and avoid group pumping the compressor. Such an adjustment leads to major complications.The present invention leads to systems that have a number of features that allow maximum ease of adjustment , along with excellent efiiciency partial load driving .According to a first embodiment of the invention, the air compressor for the auxiliary group is distinct from the air compressor turbine asso ciated with driving , and the combustion chamber for auxiliary and driving turbines are different from each other, means for controlling the admission of fuel to these chambers are interconnected so that the fuel is admitted to the cameras in a certain ratio that depends on the characteristics of the devices of the group.According to a modification, the driving turbines are in series with the auxiliary turbine and the air compressor is subdivided into two sections by the two independently driven wheels of different auxiliary turbine , adjusting beingprovided acting solely in the fuel introduction the combustion chamber or chambers .The following description given with reference to the accompanying drawings given by way of example and in no way a restrictive sense .Figure 1 schematically illustrates one embodiment of the invention;Figure 2 shows a detail of a control device applied to this embodiment ;Figure 3 shows schematically another embodiment of the invention;Figure 3a is a partial view of a modification, andFigure 4 shows a modification of the arrangement of the driving turbines .In the drive apparatus shown in FIG . 1, the auxiliary group includes two different axes driven two turbine wheels . T1 turbine wheel drives the compressor C1 which provides all the air required for the operation of the auxiliary group . The air supplied by the compressor C1 passes through the recuperator R1 and then through the combustion chamber Ch1 . The gas produced is fed turbines T1 and T2 and escapes to the atmosphere through recuperator R1.C2 compressor driven by the turbine T2 produces all the air required for driving turbines and Tmz TM1 . The air supplied by the compressor passes through the regenerator of R2 and Chz combustion chamber . Feeding the produced gas turbines driving Tim and TMZ and escapes to the atmosphere through the regenerator R2.Driving turbines Tmz TM1 and lead , respectively , the two drive shafts e1 and e2 of the vehicle through the agency of gears P , the transmission ratio of which is suitably selected . The axes a1 and a2 are arranged transversely with reference to the vehicle, i . e. in parallel with the drive shafts , while the group T1C1T2C2 shafts are arranged parallel with the longitudinal axes of the vehicle.Pressure for normal operation of the compressors C1 and C2 may be different.This drive system shows the advantage that it is not absolutely necessary to adjust the turbine equivalent opening to keep it in optimal emciency for all loads , while no pumping of compressors is avoided. The compressor 01 is driven directly by the turbine T1, and calculation shows that , without any special adjustment is maintained at all loads at its optimum efficiency. Furthermore, the compressor C2 is not connected mechanically to the turbines and Tm is necessary to satisfy the same condition for the gas temperature at the exit of th combustion chamber Cbz remain in proper relationship C2 speed , or any other equivalent variabl as its delivery pressure or the power absorbed by it. The latter is connected with the operating rate of the second turbine auxiliary cycle including T1 , which is sufficient to satisfy the above mentioned condition that the introduction of fuel into the chamber Cbz remain in a certain relation with the introduction of fuel into the chamber Chi . The relationship can be found by calculation or experience for the parameters specified in the turbines and compressors that make up the group .Adjusting the power output can be accomplished by connecting the two burners each other by mechanical means , comprising a suitable cam shown , or by other mechanical, hydraulic or electric , so that the a burner adjustment provides for adjustment of the other conditions in a desired ratio . The pro transmissions Viding for this connection can be executed, for example , by a mechanical transmission including cam and an auxiliary motor , which is the simplest form of execution. Such transmission can also be executed by any other mechanical , electrical, hydraulic or a combination thereof. Morever may be of any desired type , controlled or not , offset or the like. In the figure. 1 is connected, the execution of which involves no difficulty for one skilled in the art, is shown schematically by the dotted line I.

. Figure 2 shows by way of example and by no means in a limiting sense , an embodiment of a connection of this type . In this example, the two valve cocks and T2 1'1 inserted respectively in the fuel supply lines to the two combustion chambers and Cbz Chi are operated by means of a single control device . Carrying rods valves inside cooks undergo the action of the springs which are respectively shown in V1 and V2 corresponding to urge the valve to its open position while each spring is provided at its end with a roller is shown in 91 and g2 and maintained by the corresponding spring against a cam properly M1 or M2 . A control rod 2 that has only two cams m1 and ma can be operated in accordance with the requirements, using a lever L. It is always possible to determine , by calculation or by experiment , the relationship must be provided according to the load between the fuel supply outputs , respectively , to the combustion chambers Chz Chl and to provide for the proper design of cam contours m1 and MA in the drive arrangement illustrated in Fig . 3 TMI driving turbines , TMZ arranged as described hereinabove , each driving a drive shaft , are connected in series with the auxiliary turbines T1T2 . In this arrangement , losses through residual velocities at the outputs of the two bodies turbine form a substantial part of the entire drop when it is small . Furthermore, the temperature in the first turbine wheel T1 is limited by mechanical considerations , the temperature before the cycle will be higher and thus cycle efficiency will be higher when the drop in the wheel is greater . It is , of course , limited by the peripheral speed is required for proper use of this fall . Therefore, it is desirable , therefore reasons, to use for this cycle a pressure that is greater than in the case of the cycle illustrated in Fig . 1. The pressure should be, for example on the order of 6-8 kg . / Sq . cm . As the compressor can not be a single body, according to the invention is subdivided into two parts , each of which is controlled by one of the turbine wheels TITZ .The adjustment of the driving apparatus includes any equivalent aperture setting driving turbines or auxiliary turbines . This adjustment is carried out simply by acting on the introduction of fuel into the chamber of Chi . The calculation shows that the two bodies compres'sor automatically maintain efficiency close to its optimum at all loads .In the examples illustrated and described, turbine drivin TMI, Tmz may be any action or appropriate reaction time , and in particular , include two wheels arranged inside the same body, and rotate in the same or in opposite directions, as is illustrated in Fig . April . In the figure. 4, it is assumed that the ' turbines and Tml This turn in the same direction. Wheels are carried through the agency of the speed reduction gear PI , P2 , P3 . If the turbines were to rotate in opposite directions, would be sufficient to insert an intermediate sprocket wheels or more .According to a modification , it is possible to use the pipe system connecting a turbine with auxiliary TlTZ TmiTmz driving turbines for heating gases through Cbz chamber as shown in Fig . 3A, which therefore increases the efficiency of the cycle.In this case, the introduction of fuel into the chamber must be in connection with the introduction into the first chamber as shown with reference to the first example , to maintain the compressor and the entire cycle of near optimum efficiency in all loads.My purpose is: s I s 1. A gas turbine plant for drivin wheels of a vehicle comprising an auxiliary tur bine and a turbine operatively connected to drive the drive wheels of the vehicle, a first combustion chamber connected to feed their exhaust said auxiliary turbine , a second combustion chamber connected to feed their exhaust from the turbine at this reason, two compressors , said auxiliary turbine having two turbine wheels each supported for rotation independently of the other separate drive shafts , connected to and driven for each of said turbine wheels , respectively , each of said two compressors drivenly connected to one of said axes , whereby each of said compressors is driven independently of the other said auxiliary compressor by said turbine , each of said compressors are connected to deliver their output to one of said combustion chambers, and means for introducing fuel in each of said combustion chambers at a predetermined fixed ratio .Two . A gas turbine plant as described in claim 1. wherein the means for introducing fuel in each of said combustion chambers comprising valve means , means for controlling the adjustment of said valve means , and connection link both said regulating means , whereby the supply increase fuel to said second combustion chamber cause an increase correlated to said first combustion chamber.Three . A gas turbine plant to drive wheels of a vehicle comprising two separate lines of hot gas in series each include : an air com - '- compressor having an air intake and means under atmospheric deliveringair its respective pressure gas line independently of the other, a combustion chamber supplied by said line , a device for feeding fuel to said combustion chamber , and a gas turbine which receives the exhaust gases from the said chamber from combustion of said gas turbine is drivingly connected to the drive wheels of the vehicle , said gas turbine other1of comprising two turbine wheels independently mechanically arranged in series , each of said turbine wheels is mechanically connected respectively to one of said compressor to drive said compressor and said fuel feeding devices both of said combustion chambers are connected together in order to feed fuel to said chambers in a predetermined ratio .

Descriptionand 29 , 1951 M. H. Sedille 2554593Apparatus, including GAS TURBINES FOR DRIVING A MOTOR VEHICLE DIRECT Filed August 9, 1945 2 Sheets sheets 1 to wm om INVQAITOR YLLJalZIL and Sedille 2554593 MHL 1951 equipment, including F0 GAS TURBINE VEHICLES DIRECT DRIVING Filed August 9, 1945 2 sheets - 2 Fact INVENTOR to " ;IVW Patented May 29, 1951 Apparatus, including GAS TURBINES FOR DRIVING A MOTOR VEHICLE DIRECT Sdille Marcel Henri Louis , Paris , France , as-Signor t Societe Rateau ( Société Anonyme ) , Paris , France , a company in France Request August 9, 1945 , Serial No. 609869 In France , August 8, 1941 3 Claims . 1Vehicle driving through a gas turbine is simple when using electrical transmission . However, a certain amount of energy is wasted thereby , and it is preferable to provide a direct mechanical connection between the gas turbine and the vehicle's wheels .To employ a direct mechanical drive , it is desirable that the turbine shaft is guided transversely disposed with reference to the vehicle frame. However, the size of the drive system as a whole can not be mounted in a position transversal and therefore requires the use of a double group comprising one or more turbines driving transversely with reference to the frame, and longitudinally auxiliary group .An obvious solution would of course be to couple driving turbines and parallel auxiliary turbines . However, this provision would by necessity, as evidenced tion calculation to equivalent aperture setting for each turbine in order to provide partial loads power distribution to ensure maximum efficiency and avoid group pumping the compressor. Such an adjustment leads to major complications.The present invention leads to systems that have a number of features that allow maximum ease of adjustment , along with excellent efiiciency partial load driving .According to a first embodiment of the invention, the air compressor for the auxiliary group is distinct from the air compressor turbine asso ciated with driving , and the combustion chamber for auxiliary and driving turbines are different from each other, means for controlling the admission of fuel to these chambers are interconnected so that the fuel is admitted to the cameras in a certain ratio that depends on the characteristics of the devices of the group.According to a modification, the driving turbines are in series with the auxiliary turbine and the air compressor is subdivided into two sections by the two independently driven wheels of different auxiliary turbine , adjusting beingprovided acting solely in the fuel introduction the combustion chamber or chambers .The following description given with reference to the accompanying drawings given by way of example and in no way a restrictive sense .Figure 1 schematically illustrates one embodiment of the invention;Figure 2 shows a detail of a control device applied to this embodiment ;Figure 3 shows schematically another embodiment of the invention;Figure 3a is a partial view of a modification, andFigure 4 shows a modification of the arrangement of the driving turbines .In the drive apparatus shown in FIG . 1, the auxiliary group includes two different axes driven two turbine wheels . T1 turbine wheel drives the compressor C1 which provides all the air required for the operation of the auxiliary group . The air supplied by the compressor C1 passes through the recuperator R1 and then through the combustion chamber Ch1 . The gas produced is fed turbines T1 and T2 and escapes to the atmosphere through recuperator R1.C2 compressor driven by the turbine T2 produces all the air required for driving turbines and Tmz TM1 . The air supplied by the compressor passes through the regenerator of R2 and Chz combustion chamber . Feeding the produced gas turbines driving Tim and TMZ and escapes to the atmosphere through the regenerator R2.Driving turbines Tmz TM1 and lead , respectively , the two drive shafts e1 and e2 of the vehicle through the agency of gears P , the transmission ratio of which is suitably selected . The axes a1 and a2 are arranged transversely with reference to the vehicle, i . e. in parallel with the drive shafts , while the group T1C1T2C2 shafts are arranged parallel with the longitudinal axes of the vehicle.Pressure for normal operation of the compressors C1 and C2 may be different.This drive system shows the advantage that it is not absolutely necessary to adjust the turbine equivalent opening to keep it in optimal emciency for all loads , while no pumping of compressors is avoided. The compressor 01 is driven directly by the turbine T1, and calculation shows that , without any special adjustment is maintained at all loads at its optimum efficiency. Furthermore, the compressor C2 is not connected mechanically to the turbines and Tm is necessary to satisfy the same condition for the gas temperature at the exit of th combustion chamber Cbz remain in proper relationship C2 speed , or any other equivalent variabl as its delivery pressure or the power absorbed by it. The latter is connected with the operating rate of the second turbine auxiliary cycle including T1 , which is sufficient to satisfy the above mentioned condition that the introduction of fuel into the chamber Cbz remain in a certain relation with the introduction of fuel into the chamber Chi . The relationship can be found by calculation or experience for the parameters specified in the turbines and compressors that make up the group .Adjusting the power output can be accomplished by connecting the two burners each other by mechanical means , comprising a suitable cam shown , or by other mechanical, hydraulic or electric , so that the a burner adjustment provides for adjustment of the other conditions in a desired ratio . The pro transmissions Viding for this connection can be executed, for example , by a mechanical transmission including cam and an auxiliary motor , which is the simplest form of execution. Such transmission can also be executed by any other mechanical , electrical, hydraulic or a combination thereof. Morever may be of any desired type , controlled or not , offset or the like. In the figure. 1 is connected, the execution of which involves no difficulty for one skilled in the art, is shown schematically by the dotted line I.

. Figure 2 shows by way of example and by no means in a limiting sense , an embodiment of a connection of this type . In this example, the two valve cocks and T2 1'1 inserted respectively in the fuel supply lines to the two combustion chambers and Cbz Chi are operated by means of a single control device . Carrying rods valves inside cooks undergo the action of the springs which are respectively shown in V1 and V2 corresponding to urge the valve to its open position while each spring is provided at its end with a roller is shown in 91 and g2 and maintained by the corresponding spring against a cam properly M1 or M2 . A control rod 2 that has only two cams m1 and ma can be operated in accordance with the requirements, using a lever L. It is always possible to determine , by calculation or by experiment , the relationship must be provided according to the load between the fuel supply outputs , respectively , to the combustion chambers Chz Chl and to provide for the proper design of cam contours m1 and MA in the drive arrangement illustrated in Fig . 3 TMI driving turbines , TMZ arranged as described hereinabove , each driving a drive shaft , are connected in series with the auxiliary turbines T1T2 . In this arrangement , losses through residual velocities at the outputs of the two bodies turbine form a substantial part of the entire drop when it is small . Furthermore, the temperature in the first turbine wheel T1 is limited by mechanical considerations , the temperature before the cycle will be higher and thus cycle efficiency will be higher when the drop in the wheel is greater . It is , of course , limited by the peripheral speed is required for proper use of this fall . Therefore, it is desirable , therefore reasons, to use for this cycle a pressure that is greater than in the case of the cycle illustrated in Fig . 1. The pressure should be, for example on the order of 6-8 kg . / Sq . cm . As the compressor can not be a single body, according to the invention is subdivided into two parts , each of which is controlled by one of the turbine wheels TITZ .The adjustment of the driving apparatus includes any equivalent aperture setting driving turbines or auxiliary turbines . This adjustment is carried out simply by acting on the introduction of fuel into the chamber of Chi . The calculation shows that the two bodies compres'sor automatically maintain efficiency close to its optimum at all loads .In the examples illustrated and described, turbine drivin TMI, Tmz may be any action or appropriate reaction time , and in particular , include two wheels arranged inside the same body, and rotate in the same or in opposite directions, as is illustrated in Fig . April . In the figure. 4, it is assumed that the ' turbines and Tml This turn in the same direction. Wheels are carried through the agency of the speed reduction gear PI , P2 , P3 . If the turbines were to rotate in opposite directions, would be sufficient to insert an intermediate sprocket wheels or more .According to a modification , it is possible to use the pipe system connecting a turbine with auxiliary TlTZ TmiTmz driving turbines for heating gases through Cbz chamber as shown in Fig . 3A, which therefore increases the efficiency of the cycle.In this case, the introduction of fuel into the chamber must be in connection with the introduction into the first chamber as shown with reference to the first example , to maintain the compressor and the entire cycle of near optimum efficiency in all loads.My purpose is: s I s 1. A gas turbine plant for drivin wheels of a vehicle comprising an auxiliary tur bine and a turbine operatively connected to drive the drive wheels of the vehicle, a first combustion chamber connected to feed their exhaust said auxiliary turbine , a second combustion chamber connected to feed their exhaust from the turbine at this reason, two compressors , said auxiliary turbine having two turbine wheels each supported for rotation independently of the other separate drive shafts , connected to and driven for each of said turbine wheels , respectively , each of said two compressors drivenly connected to one of said axes , whereby each of said compressors is driven independently of the other said auxiliary compressor by said turbine , each of said compressors are connected to deliver their output to one of said combustion chambers, and means for introducing fuel in each of said combustion chambers at a predetermined fixed ratio .Two . A gas turbine plant as described in claim 1. wherein the means for introducing fuel in each of said combustion chambers comprising valve means , means for controlling the adjustment of said valve means , and connection link both said regulating means , whereby the supply increase fuel to said second combustion chamber cause an increase correlated to said first combustion chamber.Three . A gas turbine plant to drive wheels of a vehicle comprising two separate lines of hot gas in series each include : an air com - '- compressor having an air intake and means under atmospheric deliveringair its respective pressure gas line independently of the other, a combustion chamber supplied by said line , a device for feeding fuel to said combustion chamber , and a gas turbine which receives the exhaust gases from the said chamber from combustion of said gas turbine is drivingly connected to the drive wheels of the vehicle , said gas turbine other1of comprising two turbine wheels independently mechanically arranged in series , each of said turbine wheels is mechanically connected respectively to one of said compressor to drive said compressor and said fuel feeding devices both of said combustion chambers are connected together in order to feed fuel to said chambers in a predetermined ratio .

0 comments:

Post a Comment